Are Tungsten Carbide Cutting Blades Worth the Investment? A Comprehensive Review

- Share

- Issue Time

- May 30,2025

Summary

In the realm of cutting tools, tungsten carbide cutting blades have emerged as a preferred choice for both professionals and DIY enthusiasts. Known for their exceptional durability and cutting efficiency, these blades are crafted from a composite of tungsten and carbon, which gives them remarkable hardness and wear resistance.

Are Tungsten Carbide Cutting Blades Worth the Investment? A Comprehensive Review

Introduction to Tungsten Carbide Cutting Blades

In the realm of cutting tools, tungsten carbide cutting blades have emerged as a preferred choice for both professionals and DIY enthusiasts. Known for their exceptional durability and cutting efficiency, these blades are crafted from a composite of tungsten and carbon, which gives them remarkable hardness and wear resistance. At Dongcheng, we believe that understanding the benefits and applications of these blades is crucial for making an informed investment.

Understanding Tungsten Carbide: The Material Behind the Blades

What is Tungsten Carbide?

Tungsten carbide is a metallic compound that is significantly harder than steel. It is formed by combining tungsten and carbon atoms under high pressure. This unique composition results in a material that can withstand extreme conditions, making it ideal for cutting applications.

Why Choose Tungsten Carbide?

The advantages of tungsten carbide cutting blades are numerous:

High Hardness: Tungsten carbide ranks 9 on the Mohs scale of mineral hardness, making it one of the hardest materials available.

Wear Resistance: These blades resist wear and tear, providing longevity even under rigorous use.

Heat Resistance: Tungsten carbide can maintain its hardness at high temperatures, which is essential for prolonged cutting tasks.

Comparing Tungsten Carbide with Other Materials

When considering the investment in cutting blades, it is essential to compare tungsten carbide with other common materials like high-speed steel (HSS) and carbon steel.

Tungsten Carbide vs. High-Speed Steel (HSS)

Durability: Tungsten carbide blades outlast HSS blades significantly, making them a cost-effective choice over time.

Edge Retention: Tungsten carbide maintains a sharper edge longer than HSS, reducing downtime for sharpening.

Cost: While tungsten carbide blades may have a higher upfront cost, their longevity and performance can lead to lower overall expenses.

Tungsten Carbide vs. Carbon Steel

Performance: Tungsten carbide offers superior cutting performance, especially for hard materials.

Lifespan: Carbon steel blades wear down much faster, necessitating frequent replacements.

Heat Resistance: Tungsten carbide performs better under high temperatures, which is critical in industrial settings.

Applications of Tungsten Carbide Cutting Blades

Woodworking

In woodworking, tungsten carbide cutting blades are widely used in saws, routers, and planers. Their ability to cut through hardwoods and softwoods alike makes them indispensable for carpenters and woodworkers.

Metalworking

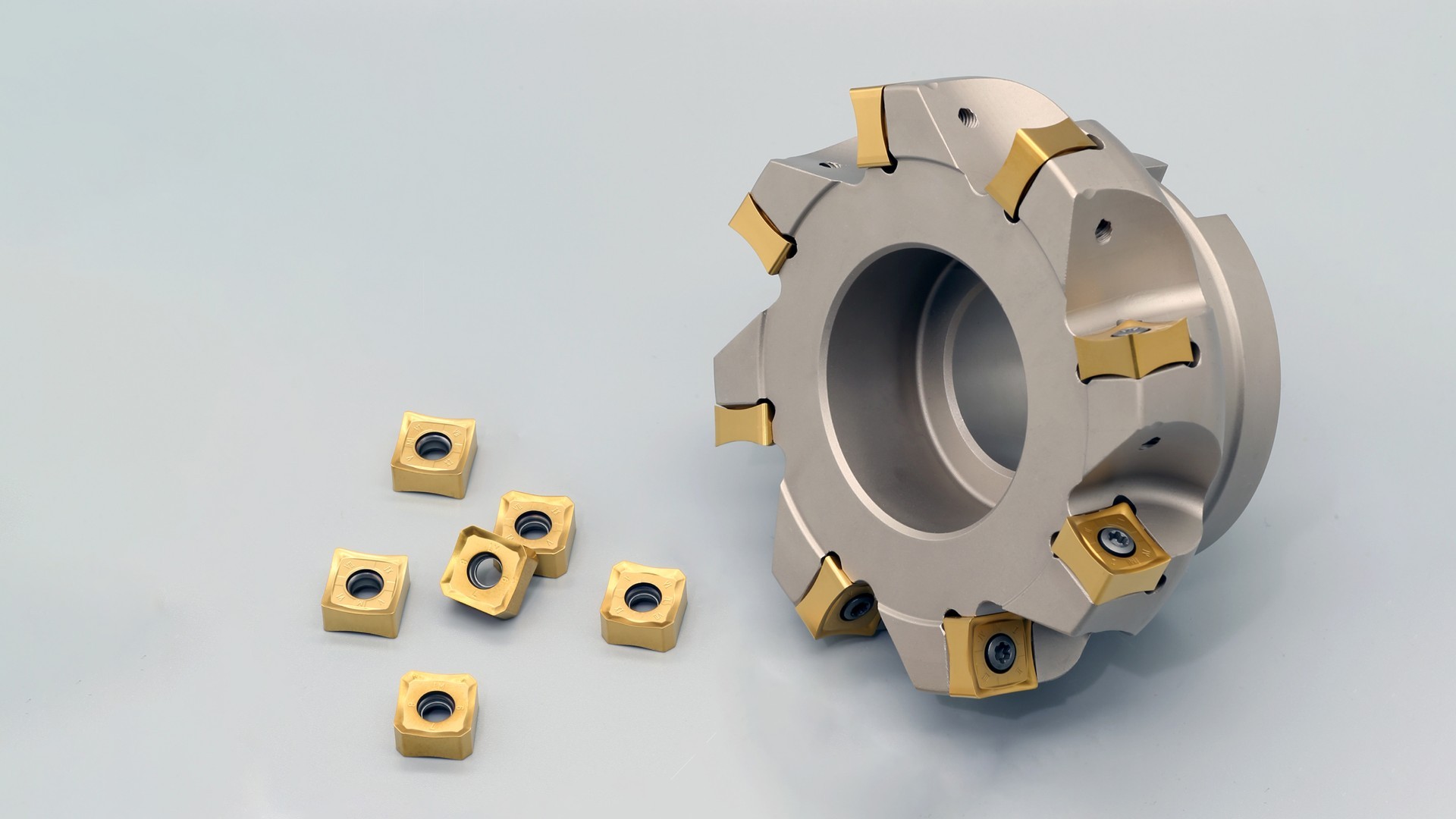

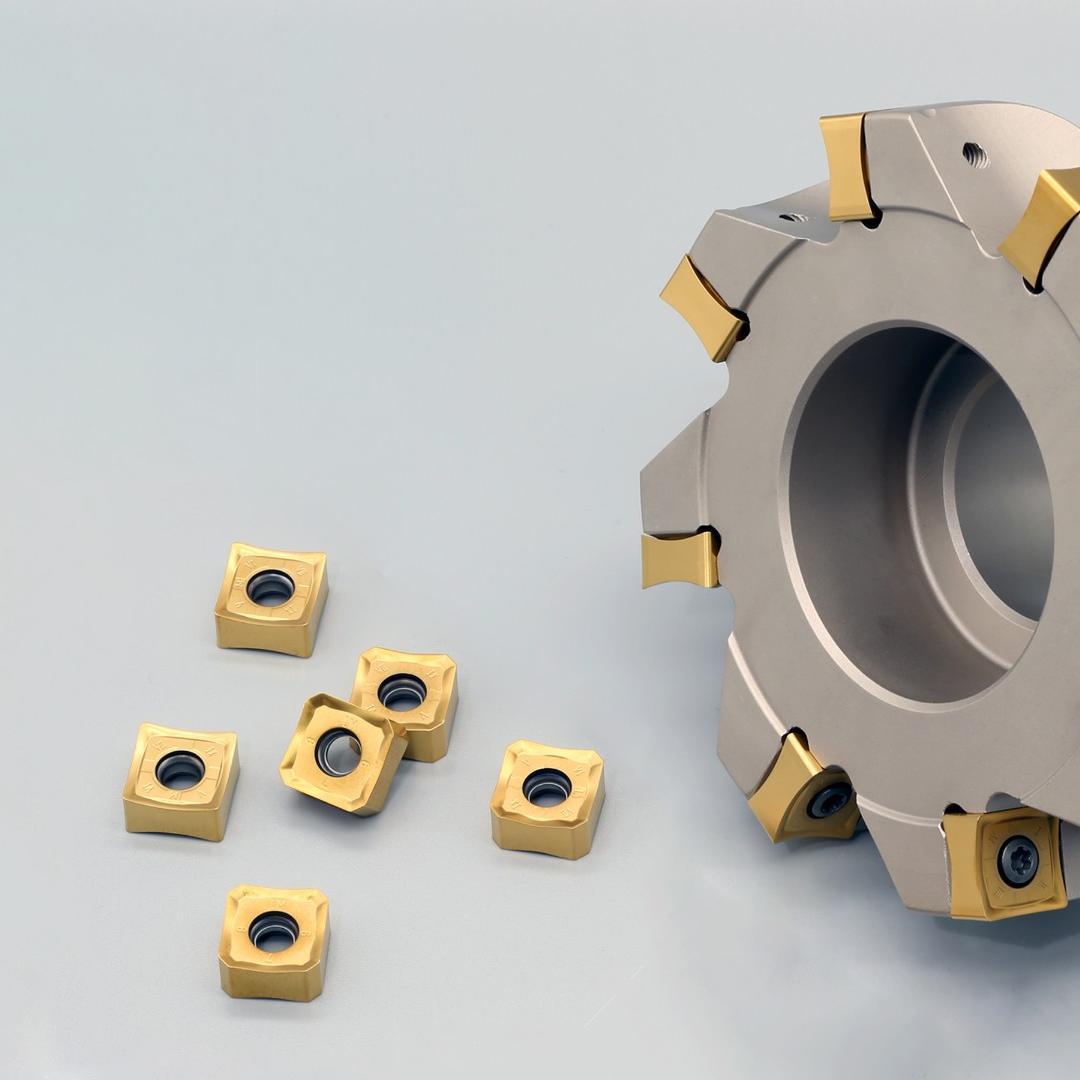

In metalworking, tungsten carbide blades excel in cutting and shaping metals. They are commonly used in lathes and milling machines, providing precision and efficiency.

Construction and Demolition

For construction and demolition applications, tungsten carbide blades are ideal for cutting through concrete, brick, and other tough materials. Their durability ensures that they can handle the demands of heavy-duty work.

Benefits of Investing in Tungsten Carbide Cutting Blades

Cost-Effectiveness

While the initial purchase price of tungsten carbide cutting blades may be higher than other materials, their long lifespan and reduced need for frequent replacements make them a cost-effective choice in the long run. This investment pays off through increased productivity and reduced downtime.

Enhanced Performance

Tungsten carbide blades offer superior cutting performance. They maintain sharpness longer and provide smoother cuts, which translates to better quality work. This enhanced performance is particularly important in professional settings where precision is paramount.

Reduced Maintenance

With tungsten carbide blades, users experience less frequent sharpening and maintenance. This advantage allows for more time spent on actual work rather than blade upkeep, further enhancing productivity.

Choosing the Right Tungsten Carbide Cutting Blade

Blade Types and Specifications

At Dongcheng, we offer a variety of tungsten carbide cutting blades tailored to different applications. Understanding the specifications is key to choosing the right blade:

Tooth Count: A higher tooth count provides a smoother finish, while a lower count is better for faster cuts.

Blade Diameter: The diameter of the blade should match the tool it will be used with, ensuring compatibility and performance.

Kerf Width: The kerf width affects the amount of material removed during cutting. Thinner kerfs create less waste.

Quality and Brand Reputation

Investing in high-quality blades from reputable brands like Dongcheng ensures reliability and performance. Quality blades are engineered for precision and are subjected to rigorous testing.

How to Maintain Tungsten Carbide Cutting Blades

Proper Cleaning Techniques

Keeping your tungsten carbide blades clean is essential for maintaining their performance. After each use, blades should be cleaned to remove resin, pitch, and metal shavings. Use a soft brush and mild cleaning solution to avoid damaging the blade.

Storage Solutions

Proper storage is vital to prolonging the life of your blades. Store them in a dry, protected environment, preferably in a blade case or holder to prevent accidental damage.

Sharpening Methods

While tungsten carbide blades maintain their sharpness longer, they will eventually require sharpening. Professional sharpening services are recommended to ensure the proper angle and precision are maintained.

Conclusion: Are Tungsten Carbide Cutting Blades Worth the Investment?

In conclusion, the advantages of tungsten carbide cutting blades far outweigh the initial investment costs. Their superior durability, cutting performance, and cost-effectiveness make them an essential tool for professionals across various industries. At Dongcheng, we stand by the quality of our tungsten carbide blades, ensuring that you receive the best tools for your cutting needs.

Investing in tungsten carbide cutting blades means investing in efficiency and precision. For those serious about their craft, these blades are not just worth the investment; they are a necessary component for achieving the highest standards of work.