Tungsten Carbide Cutting Blades: The Best-Kept Secret for Metalworking Excellence

- Share

- Issue Time

- Jun 25,2025

Summary

In the realm of metalworking, the choice of cutting tools can significantly influence productivity, precision, and overall operational costs. Among the myriad options available, tungsten carbide cutting blades stand out as the ultimate solution for demanding industrial applications.

Tungsten Carbide Cutting Blades: The Best-Kept Secret for Metalworking Excellence

In the realm of metalworking, the choice of cutting tools can significantly influence productivity, precision, and overall operational costs. Among the myriad options available, tungsten carbide cutting blades stand out as the ultimate solution for demanding industrial applications. At Dongcheng, we have perfected the art of manufacturing high-performance tungsten carbide blades designed to meet the rigorous standards of modern manufacturing. Our blades are engineered to provide unmatched durability, precision, and efficiency, making them the best-kept secret for professionals seeking to elevate their metalworking capabilities.

Why Tungsten Carbide Is the Material of Choice for Cutting Blades

Tungsten carbide is a composite material composed of tungsten and carbon atoms, fused through a sintering process. Its exceptional properties make it the go-to material for cutting blades in various industrial applications:

Exceptional Hardness: Tungsten carbide ranks among the hardest materials available, second only to diamonds. This hardness allows it to cut through tough metals with minimal wear.

High Wear Resistance: The resilience of tungsten carbide ensures that blades maintain their sharpness over extended periods, reducing the frequency of replacements.

Superior Thermal Stability: Tungsten carbide can withstand high temperatures generated during cutting operations without losing its structural integrity.

Corrosion Resistance: Unlike steel, tungsten carbide blades resist corrosion, making them suitable for cutting various metals, including stainless steel and other corrosive alloys.

Cost-Effectiveness: While initially more expensive than traditional steel blades, tungsten carbide blades provide long-term savings due to their extended lifespan and consistent performance.

Advantages of Using Tungsten Carbide Cutting Blades in Metalworking

Investing in tungsten carbide blades offers numerous benefits that can revolutionize your manufacturing process:

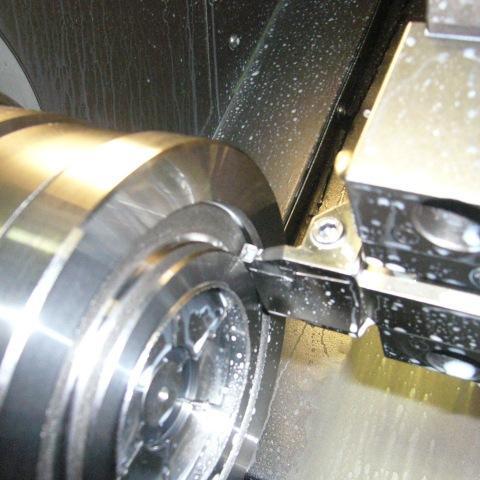

1. Enhanced Cutting Precision and Finish

Tungsten carbide blades produce cleaner cuts with minimal burrs and rough edges, resulting in superior surface finishes. This precision reduces the need for secondary finishing processes, saving time and labor costs.

2. Increased Tool Life and Reduced Downtime

The durability of tungsten carbide drastically extends the lifespan of blades. This longevity translates into fewer blade changes, minimizing machine downtime and boosting overall productivity.

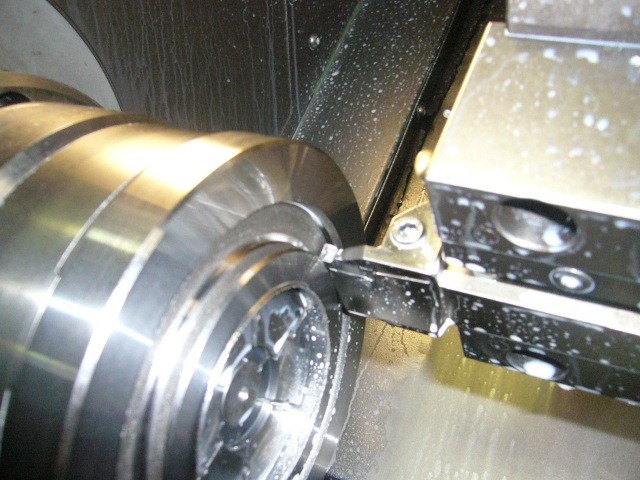

3. Superior Performance on Hard Metals

Unlike traditional steel blades, tungsten carbide blades excel at cutting hard metals such as stainless steel, titanium, nickel alloys, and hardened steels. Their strength allows for faster cutting speeds without compromising quality.

4. Higher Cutting Speeds and Efficiency

The high thermal stability of tungsten carbide enables higher cutting speeds, leading to faster throughput and improved efficiency in manufacturing lines.

5. Reduced Operating Costs

Although tungsten carbide blades have a higher initial cost, their longer lifespan and reduced replacement frequency result in lower overall operational expenses.

Dongcheng’s Tungsten Carbide Cutting Blades: Setting the Industry Standard

Dongcheng has established itself as a leader in manufacturing high-quality tungsten carbide blades. Our commitment to innovation, precision engineering, and customer satisfaction ensures that our blades outperform competitors in every aspect:

Manufacturing Excellence

Our blades are produced using state-of-the-art sintering technology and strict quality control protocols. This guarantees consistent hardness, toughness, and dimensional accuracy across all products.

Custom Solutions for Diverse Applications

We understand that different industries have unique cutting requirements. Dongcheng offers customized tungsten carbide blades tailored for specific materials, thicknesses, and cutting conditions. Whether for metal fabrication, automotive, aerospace, or industrial machining, our blades deliver optimal performance.

Innovative Blade Designs

Our team invests heavily in research and development, resulting in innovative blade geometries that enhance cutting efficiency, chip evacuation, and blade longevity.

Environmental and Safety Standards

Dongcheng prioritizes eco-friendly manufacturing practices and worker safety, ensuring that our blades meet or exceed all industry environmental regulations.

Applications of Tungsten Carbide Cutting Blades in Metalworking

The versatility of tungsten carbide blades makes them suitable for a broad spectrum of metalworking applications:

1. Metal Cutting and Shearing

Ideal for precision cutting of sheets, plates, and bars in manufacturing plants, our blades deliver clean cuts on stainless steel, aluminum, copper, and other metals.

2. Circular Saw Blades

Our tungsten carbide-tipped circular saw blades are perfect for cutting thick metals with minimal vibration and vibration damping, ensuring smooth operation and long blade life.

3. Slitting and Trimming

Used extensively in coil processing, our blades provide precise slit widths and consistent trimming, essential for high-volume production.

4. Die and Mold Manufacturing

Tungsten carbide blades excel in milling and shaping metal molds, thanks to their high hardness and resistance to deformation under heavy loads.

5. Cutting Hard-to-Machine Alloys

For hardened steels and titanium alloys, tungsten carbide blades are indispensable, offering superior cutting speeds and extended tool life.

Choosing the Right Tungsten Carbide Blade: Key Factors

To maximize the benefits of tungsten carbide blades, it’s essential to select the appropriate blade type for your specific application:

Blade Geometry: The tooth design, angle, and cutting edge influence cut quality and material compatibility.

Grade of Tungsten Carbide: Different grades offer varying hardness, toughness, and resistance to wear.

Coating Options: Applying tungsten carbide coatings or diamond-like carbon (DLC) layers can further enhance performance.

Blade Thickness and Diameter: Must match machine specifications and material thickness for optimal results.

Dongcheng’s expert consultants can assist in selecting the best blade configuration to meet your operational demands.

Maintenance and Best Practices for Tungsten Carbide Blades

Proper maintenance ensures maximum blade lifespan and performance consistency:

Regular Inspection: Check for chips, cracks, or wear patterns before each use.

Proper Storage: Store blades in dry, protected environments to prevent surface contamination.

Correct Mounting: Ensure proper alignment and tightening to avoid uneven wear.

Optimal Cutting Parameters: Use appropriate feed rates, speeds, and cooling to prevent overheating and premature wear.

Cleaning Procedures: Remove metal debris and residues after each use to maintain cutting efficiency.

Why Choose Dongcheng Tungsten Carbide Blades?

Dongcheng is dedicated to delivering industry-leading tungsten carbide blades that exceed expectations. Our comprehensive quality management, customized solutions, and dedicated customer support distinguish us from competitors. Partnering with Dongcheng guarantees access to cutting-edge technology, innovative designs, and unmatched durability.

Conclusion: Elevate Your Metalworking with Tungsten Carbide Blades by Dongcheng

In the competitive world of metalworking, precision, durability, and efficiency are non-negotiable. Tungsten carbide cutting blades represent the best investment for manufacturers aiming to maximize productivity and minimize downtime. With Dongcheng’s advanced manufacturing processes and customer-centric approach, our tungsten carbide blades are the ultimate choice for professionals seeking superior performance across all metalworking applications.

Harness the power of tungsten carbide—experience longer-lasting blades, faster cuts, and exceptional quality with Dongcheng. Transform your manufacturing process today and discover why tungsten carbide blades are the best-kept secret for industry leaders worldwide.

Contact Dongcheng today to explore our range of custom tungsten carbide cutting blades and discover solutions tailored to your specific needs.