From Hobbyist to Professional: Mastering the Power of Tungsten Carbide Cutting Blades by Dongcheng

- Share

- Issue Time

- Jul 9,2025

Summary

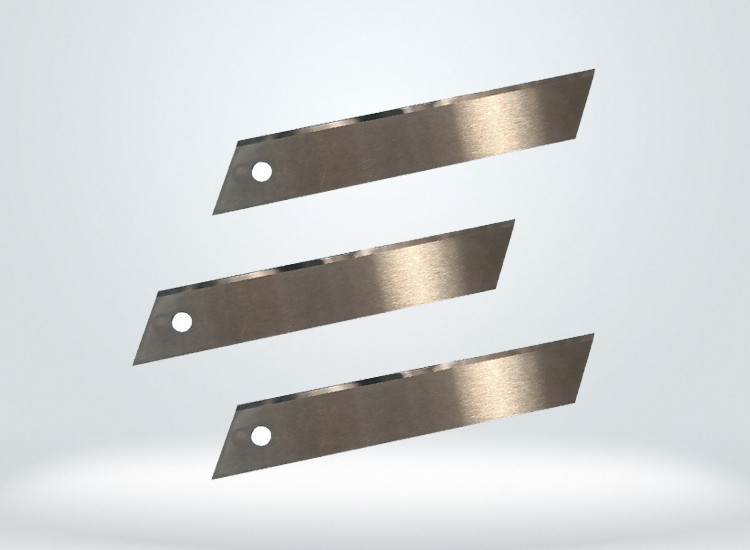

Discover how Dongcheng's premium tungsten carbide cutting blades can elevate your craftsmanship from hobbyist to professional level. Unmatched precision, durability, and performance for all cutting needs.

From Hobbyist to Professional: Mastering the Power of Tungsten Carbide Cutting Blades by Dongcheng

Introduction: The Evolution of Cutting Tools from Hobbyist to Professional Use

Transitioning from a hobbyist to a professional craftsman demands more than passion; it requires precision tools that deliver consistent performance, durability, and efficiency. Tungsten carbide cutting blades have revolutionized the cutting industry, providing a superior alternative to traditional steel blades. At Dongcheng, we believe in empowering artisans, manufacturers, and industrial professionals with cutting-edge tungsten carbide blades that elevate their work to new heights.

This comprehensive guide explores the intricacies of tungsten carbide blades, their advantages over conventional tools, and how Dongcheng’s innovative manufacturing processes guarantee unmatched quality. Whether you are involved in woodworking, metal fabrication, stone cutting, or specialized industrial applications, understanding the full potential of tungsten carbide blades will transform your approach from amateur to expert.

Why Tungsten Carbide Is the Material of Choice for Cutting Blades

Unparalleled Hardness and Wear Resistance

Tungsten carbide ranks among the hardest materials used in cutting tools, second only to diamond. Its extreme hardness ensures that blades maintain their sharpness over extended periods, even when used on the toughest materials such as ceramics, metals, and dense composites. This wear resistance significantly reduces the frequency of blade replacements, translating into cost savings and increased productivity.

Exceptional Impact and Heat Resistance

Unlike traditional steel blades, tungsten carbide blades resist deformation and maintain structural integrity under high-impact forces and elevated temperatures generated during cutting. This thermal stability allows for faster cutting speeds without compromising quality, making them ideal for industrial applications where speed and precision are paramount.

Superior Precision and Finish

The sharpness retention of tungsten carbide blades ensures clean, precise cuts with minimal burrs or rough edges. This is especially critical in industries such as aerospace, electronics, and fine woodworking, where accuracy directly affects the final product quality.

Dongcheng’s Commitment to Excellence in Tungsten Carbide Blade Manufacturing

Advanced Manufacturing Techniques

At Dongcheng, we utilize state-of-the-art sintering technology, precision grinding, and quality control protocols to produce tungsten carbide blades that exceed industry standards. Our strict quality assurance ensures each blade features uniform hardness, perfect edge geometry, and optimal balance.

Customizable Blade Designs for Diverse Applications

Recognizing that different industries have unique needs, Dongcheng offers a wide range of blade sizes, tooth configurations, and edge treatments. Whether you require segmented blades for large-scale cutting or fine-tooth blades for detailed work, our custom solutions guarantee superior performance.

Innovative Coatings for Enhanced Durability

Our blades are often coated with titanium nitride (TiN) or other advanced coatings to further improve corrosion resistance, reduce friction, and extend service life. These coatings are meticulously applied to maximize blade longevity and minimize downtime.

Applications of Tungsten Carbide Cutting Blades by Dongcheng

Woodworking and Carpentry

Dongcheng’s tungsten carbide blades excel in cutting hardwoods, laminated panels, and veneered surfaces. Their sharp edges and heat resistance allow for smooth, splinter-free cuts, significantly improving finish quality and workflow efficiency.

Metal Fabrication and Cutting

Our blades are engineered to slice through ferrous and non-ferrous metals with minimal deformation. They are ideal for steel, aluminum, copper, and brass, providing clean cuts that reduce material wastage and post-cut finishing.

Stone and Tile Cutting

For ceramics, granite, marble, and other dense stones, tungsten carbide blades deliver precise, chip-free cuts. Their resilience against abrasive materials makes them the go-to choice for tile installers and stone fabricators seeking high-quality results.

Industrial and Specialty Applications

Dongcheng’s blades are also used in electronics manufacturing, aerospace component machining, and composite material processing. Their adaptability and robust performance make them suitable for high-volume, high-precision industrial tasks.

Choosing the Right Tungsten Carbide Blade for Your Needs

Assessing Material Type and Thickness

The material being cut and its thickness are critical factors in selecting the optimal blade. Thicker or harder materials require blades with higher-grade tungsten carbide and specific tooth geometries to ensure efficient cutting.

Determining Tooth Configuration and Blade Diameter

Fine-tooth blades are perfect for detailed, precise cuts.

Coarse-tooth blades are suited for rough cuts and rapid material removal.

Segmented blades offer longer life and are ideal for large-scale industrial cutting.

Considering Coatings and Special Features

Depending on the application, you may need blades with special coatings for corrosion resistance or reduced friction. Additionally, features like vacuum slots or laser-cut expansion slots can enhance performance and reduce vibration.

Maintenance and Safety Tips for Tungsten Carbide Cutting Blades

Proper Handling and Storage

Treat tungsten carbide blades with care to avoid chipping or cracking. Store them in protective cases or organized racks to prevent accidental damage.

Regular Inspection and Sharpening

Periodic inspection for dull edges, cracks, or deformation is essential. Although tungsten carbide blades retain sharpness longer, professional sharpening or reconditioning may be necessary for optimal performance.

Safe Operating Practices

Always wear appropriate personal protective equipment (PPE), including gloves and eye protection. Use correct feed rates and avoid excessive force to prolong blade life and ensure safety.

Why Choose Dongcheng Tungsten Carbide Blades?

Unmatched Quality and Consistency

Dongcheng’s rigorous quality control guarantees that every blade is manufactured to exact specifications, ensuring consistent performance across batches.

Innovative Design and Customization

Our dedicated R&D team continuously innovates to develop new blade geometries and coatings tailored to industry-specific challenges.

Competitive Pricing and Exceptional Customer Service

We provide cost-effective solutions without compromising quality. Our expert support team is available to assist with product selection, technical advice, and after-sales support.

Conclusion: Elevate Your Craftsmanship with Dongcheng Tungsten Carbide Blades

Transitioning from hobbyist to professional demands tools that deliver superior precision, durability, and efficiency. Dongcheng’s premium tungsten carbide cutting blades are engineered to meet and exceed these demands, empowering craftsmen, manufacturers, and industrial operators to achieve excellence in every cut.

Invest in Dongcheng’s tungsten carbide blades and experience unmatched performance, longer service life, and consistent quality that will transform your work process. Whether you are cutting wood, metal, stone, or composites, trust in Dongcheng’s innovative solutions to elevate your craftsmanship.

Choose Dongcheng for the ultimate in tungsten carbide cutting technology—where precision meets durability, and professional standards are the norm.